If you are running a company, inventory management software development is a must!

Yeah, we know, we know, every warehouse or manufacturing unit has its own methods. Some are doing it on paper and others, NOT AT ALL.

But this is the 21st century and supply chain management is one of the key focuses of Industry 4.0. The world’s biggest organizations across the world are handling their smarts with inventory management systems, with the likes of Amazon, FedEx, and Alibaba being at the forefront of it.

Speaking of which, inventory management systems have become a must ever since the supply chain shifted following the pandemic. If you are new to the whole concept, and considering integrating inventory management software into your warehouse or factory, this inventory management system development guide is for you.

In our guide to inventory management systems, we shall be discussing everything you need to know about inventory management software and everything else related to the same. By the end, you will have all the information you need.

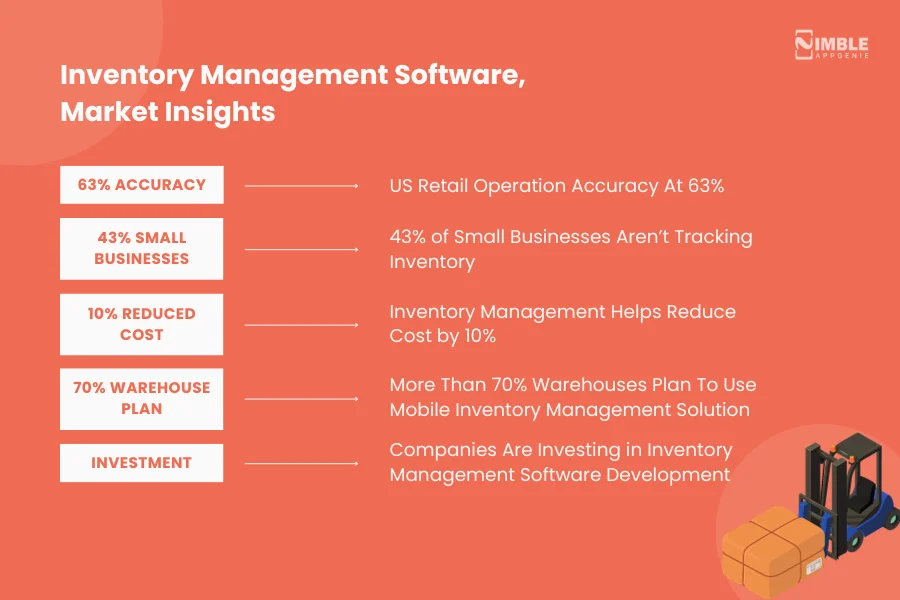

Inventory Management Software and Market Insights

Let’s start our guide with a dive into the industrial insights of the inventory management software market.

So, here we go:

► US Retail Operation Accuracy At 63%

The United States of America is an industrial heaven and houses some of the largest retail markets in the world.

While the manufacturing and selling side is booming and growing faster than ever, we can’t say the same about inventory management.

Several reports show, average inventory accuracy of U.S. retail operations is around 63%.

This might not seem like a bad number, but in a business scenario where unmanaged inventory can mean loss of a customer or loss of business, this is huge. Not to mention the bad consumer experience it creates.

All in all, there is a clear gap that can use some improvement and order in chaos. This is where the inventory management system can shine.

► 43% of Small Businesses Aren’t Tracking Inventory

If you are a business owner, you know the secret to success is planning and execution.

However, the reality is quite different. Many reports and surveys show us that more than 43% of small businesses in the market are not tracking their inventory, still putting their faith in the old pen-and-paper method.

Moreover, the other 21% of businesses claim they don’t have any stock at all. These are some criteria your business will do well to avoid falling in.

► Inventory Management Helps Reduce Cost by 10%

Barely into the inventory management software development guide, we already have the positive impact inventory management softwares are making in the market.

One of the largest issues in the inventory field is the issue of overstocking and understocking. The reason behind them usually is the poor planning and lack of management, as companies don’t even know what they need.

However, when you fix these two issues with the help of general or industrial inventory management software, what we get is a significant 10% reduction in inventory costs.

► More Than 70% Warehouses Plan To Use Mobile Inventory Management Solution

It goes without saying that one of the biggest targets of Industry 4.0 is warehouse management and supply chain optimization.

A trusted source, ValuTrack, says that around 73% of warehouses are planning to use mobile inventory management solutions.

It goes without saying combining mobile solutions in addition to inventory management software development reaps many benefits, as the majority of the workforce are already familiar with mobile interfaces.

It also makes it a lot easier to handle devices in high-risk workplaces.

► Companies Are Investing in Inventory Management Software

It is no secret that inventory management software is the natural next step in the overall growth of the industry.

As a result of this common urge to innovate, we have seen a great shift in companies moving towards inventory management software solutions.

Consequently, inventory management software market spending will also increase in the U.S.A. by around 8.3% between 2022 and 2028, says futuremarketinsights.

These are some of the key statistics that show booming growth in the inventory management software market. And with this out of the way, let’s go through the overview of this core concept.

What Is Inventory Management Software?

Before diving into more technical aspects of concept, let’s first understand what inventory management systems are.

The term “inventory management software” refers to a system that helps in the management and automation of inventory. The capabilities of an inventory management software system include tracking inventory, procurement, updating accounting data, synchronization across different locations, and much more.

Here, inventory can be anything ranging from assets to finished goods or even raw materials.

Also known as inventory management software, these software are quite beneficial, thus, used across different industries. This includes:

- Warehouses

- Supply Chain Management

- Manufacturing Units

- eCommerce Companies

- Retail Stores

- Investment companies

- Wholesalers & Distributors

And so on.

This system makes inventory management much easier as compared to the traditional pen & paper method. Consequently, it saves a lot of time, effort, and less chances of human error.

We will be going through the entire development process later down the line. Meanwhile, let’s go through the different types of learning management systems.

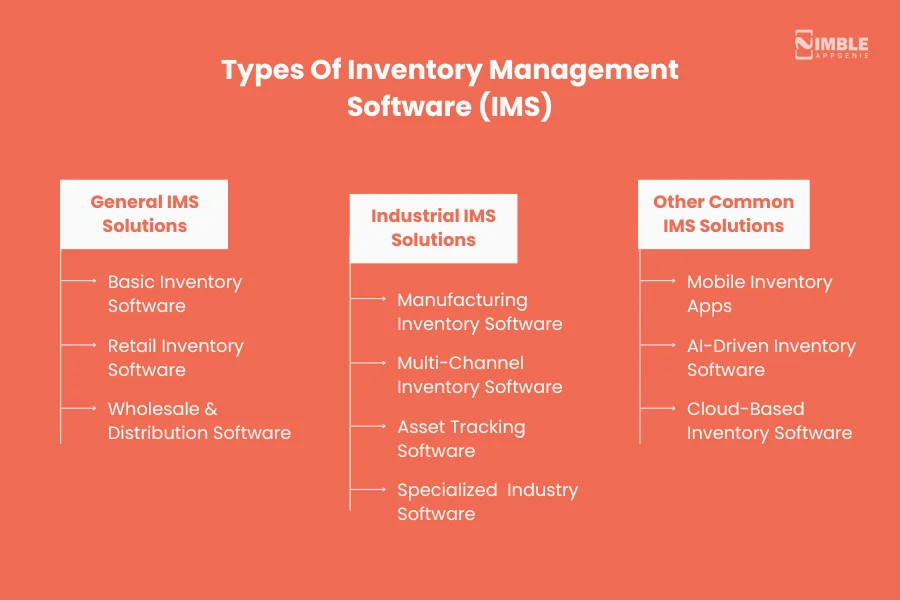

Types of Inventory Management Software

Inventory is a term and concept that is used in a range of different industries.

Consequently, there are one-store retail stores that are using inventory management solutions as well as multinational multi-billion dollar manufacturing and/or supply chain companies.

However, there is a huge difference in the needs of both users. This is what gives us types of inventory management software based on use.

As such, the solution can be divided into two types. These are, as mentioned below:

Type 1: General Inventory Management Software Solutions

Let’s start with “general” inventory management software.

The term “general” refers to the commonly used inventory management solution which doesn’t require any special functionality.

However, depending on the organization, general inventory management can be divided into different types.

These are, as mentioned below.

Basic Inventory Software

As the name suggests, these are the basic inventory management solutions that fulfill the need for simple inventory tracking. These are perfect fit for small businesses that are rising in numbers these days.

Retail Inventory Software

Retail inventory software is designed with retail businesses in mind. Since the majority of retail stores sell stuff to walk in customer, this inventory management software is integrated with point-of-sale (POS) capabilities.

Wholesale and Distribution Software

Moving a step above retail stores, we have wholesalers and distributors. Now, when compared to retail stores, this segment is handling way more stuff, covering multiple warehouses. And consequently, they need much more capacity. This is where wholesale & distribution software comes in as a type of Inventory Management Software.

Now that we are done with the general types of inventory management systems, let’s move to industrial inventory management software.

Type 2: Industrial Inventory Management Software Solutions

Let’s understand industrial inventory management software.

As the trends of adding “industrial” in front of concepts go, here, it refers to solutions that are made at industrial standards.

These standards are usually much larger, requiring higher quality and accuracy. After all, these types of inventory management software are used by companies like Amazon, Walmart, FedEx, and so on.

Now, there are so many different industries with all of them having unique needs. This gives us a range of different types of inventory management system development.

Take a look at them below.

Manufacturing Inventory Software

The name says it all. This form of industrial inventory management software is designed for factories and manufacturing facilities. Therefore, this software also offers support for BOM and work-in-progress tracking.

Multi-Channel Inventory Software

Moving from manufacturing to selling, we have multi-channel inventory software. Larger retail companies aren’t just on one channel. Rather, they are generating revenue from lots of different sources. To keep all of them tracked and in check, we have multi-channel inventory software.

Asset Tracking Software

Big companies handle big assets. Talk of hedge funds, real estate companies, and so on. And to keep track of these big numbers, what is better than inventory management software? This is quite similar to custom CRM development needs in these industries.

Specialized Industry Software

There are some super-specific industries that also have equally specific needs, for example healthcare tech companies, food, or pharmaceutical firms. To accommodate their needs, we go for this form of inventory management system development.

Type 3: Other Common Types of Inventory Management Software

Above we discussed two major inventory management software types. However, there are some inventory management software solutions that don’t fall into either of those categories. Let’s have a look at them, here:

Mobile Inventory Apps

So, how are mobile inventory apps different from your usual inventory management solution? Well, the answer is it isn’t. Rather, this is what you get when you combine mobile app development with inventory management software. These apps work as an extension of existing inventory software.

AI-Driven Inventory Software

Well, well, we all knew AI was going to appear sooner or later. So, what happens when you embed AI and ML technologies into inventory systems? The answer is, you get modern inventory management software with forecasting and prediction capacities.

Cloud-Based Inventory Software

Now we are moving from scale to technology in terms of criteria. Cloud-based inventory software is a good example of SaaS development integration in the supply chain, which by the way is a mega trend in Industry 4.0.

These are the different types of inventory software. With this out of the way, it’s time to understand the inventory management system workflow.

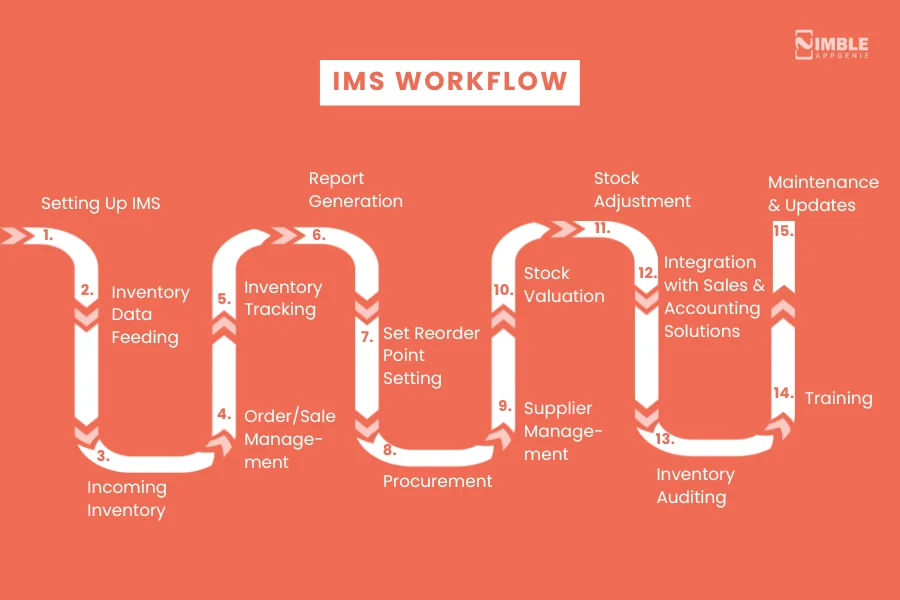

How Does Inventory Management Software Work?

Now that we know what inventory management software is and their different types, it’s time to ask an important question:

“How Does Inventory Management Software Work?”

Now, this can be a little more complex than you might have imagined at first but bear with us. In this section of our guide to the inventory management system, we shall be going through a detailed inventory management software workflow.

Therefore, with this being said, let’s get right into it:

1. Setting Up Inventory Management Software

The very first step is setting up an inventory system and integrating it with the company’s IT infrastructure.

In layman’s terms, this is where we install the inventory management software on the network or computer, whatever model the company is working on.

Following this, the team also has to set up specific user accounts, setting control access in the said hierarchy.

2. Inventory Data Feeding

Now that we are done with the inventory system setup, it’s time to feed the data.

Assuming that you already have an inventory in your warehouse or shelf, we have to feed data to the software.

Inventory data includes:

- Product Names

- Descriptions

- SKU (Stock Keeping Unit) Numbers

- Supplier Information

- Inventory Location

And so on.

Barcode Scanning (if applicable)

This step is only applicable if your businesses manage inventory via barcodes, which is quite common practice today.

Barcode scanner devices directly connect with inventory management software systems on the company network and update data when an item is scanned. However, the business has to set barcode product details to the software beforehand.

3. Incoming Inventory

With the basic setup done, it’s time to move forward to more advanced and ongoing processes. The first one is, accounting for incoming inventory.

Every business that deals in inventory will receive new articles at regular intervals of time. Though it is also based on demand and need.

In any case, when the businesses receive the new inventory, it has to be updated on the inventory management software. Also, it helps verify whether the received amount matches the purchase order.

4. Order/Sale Management

Order management or sales management comes into action when a customer places an order. Now, depending on the nature of the business, it can be small orders or entire containers.

In any case, in this instance, the concerned team or person will create a sales order in the software. This is something that can be automated using AI and ML technologies, saving a lot of time and also reducing the chance of human error.

Once the data is fed to the system, inventory management software will deduct it from available stock. If the business is dealing with multiple locations and has shared inventory, the information will be updated across the system.

5. Inventory Tracking

This is not a step, but rather a process that goes on for the entire duration. What happens here is that the business has to continuously monitor inventory levels. This is done to ensure that the information we are dealing with is accurate.

Furthermore, top inventory management software has a feature that sends notifications or alerts when you are running low on specific items.

6. Report Generation

If there’s one thing that Agile methodology teaches us, it is that reporting is important to keep a streamlined process going smoothly.

So, here, we generate a report via the inventory management system. Through the thorough analysis of this report, we can figure out sales trends, stock levels, and valuation reports. Or more modern software already provides a well-documented report with all the information.

In either case, the data can be used for important decisions like ordering quantity and restocking, bringing us to our next step.

7. Set Reorder Point Settings

Using the information we gathered in the last step helps businesses set a reorder point.

What are reorder points? – Reorder points in the context of inventory management refers to the levels at which new purchase orders for certain items will be dispatched to bring inventory back to the desired level.

It goes without saying that setting reorder points is super important if a business wants to maintain inventory and don’t fall in 63% of businesses who don’t keep a record of their inventory or worse 21% who have no stock at all.

8. Procurement

When you reach the set “reorder point” it’s time to go for “procurement”.

If you are looking for inventory management software, you already know what this term means, but for those who don’t know: it refers to buying goods or items.

Coming back, the business will create a purchase order for the concerned items when they reach the reorder point. The order should include supplier information, quantities, and expected delivery dates.

9. Supplier Management

While some businesses are suppliers themselves or get their items from just one supplier, there are others who have to work with a dozen.

In either case, supplier management is very important, making it a core feature of inventory management solutions.

Here, the business has to maintain information such as contact details and pricing agreements. In addition to this, the inventory software enables supplier performance tracking.

10. Stock Valuation

Here’s amazing inventory management system functionality: stock valuation.

The software helps the team calculate the total value of inventory. The factors considered here are goods’ cost and quantities at hand.

The information discussed here is very information for business, since we are talking about money. In addition to this, it also helps with financial reporting and tax calculations.

11. Stock Adjustment

Nothing is pinpoint accurate and when you are in a retail or manufacturing business, few stolen, damaged, or lost goods are to be expected.

Based on this information, we need to make stock adjustments. In addition to the adjustment quantity and items, it’s also advised to document the reason.

12. Integration with Sales and Accounting Solutions

So, this is something that may or may not be applicable to you based on the nature and size of your business.

What we are talking about is, integrating inventory management software with accounting and sales systems. This also enables seamless internal data exchange and financial reporting, as well as cost tracking.

13. Inventory Auditing

The software is accurate, but nothing is foolproof. That’s why it’s advised to conduct periodic physical inventory audits.

This helps businesses make sure their software is working fine, ensuring quantities in their software and actual stock match up. If there are any discrepancies, they will be identified and resolved.

14. Training

Staff training is an important part of keeping the team updated with how the software works. This is especially important when the business is switching from manual processes to inventory management software.

Here, you have to train them how to use inventory software effectively. This might be a little time-consuming, but it pays off in the longer term.

15. Maintenance and Updates

Maintenance and updates of the software are important for various reasons. For one, as the business grows, its requirements also change. It is dealt with by introducing new features and additional functionality.

In addition to this, it is also done to correct errors in the software, make it more compliable, and suitable for business needs.

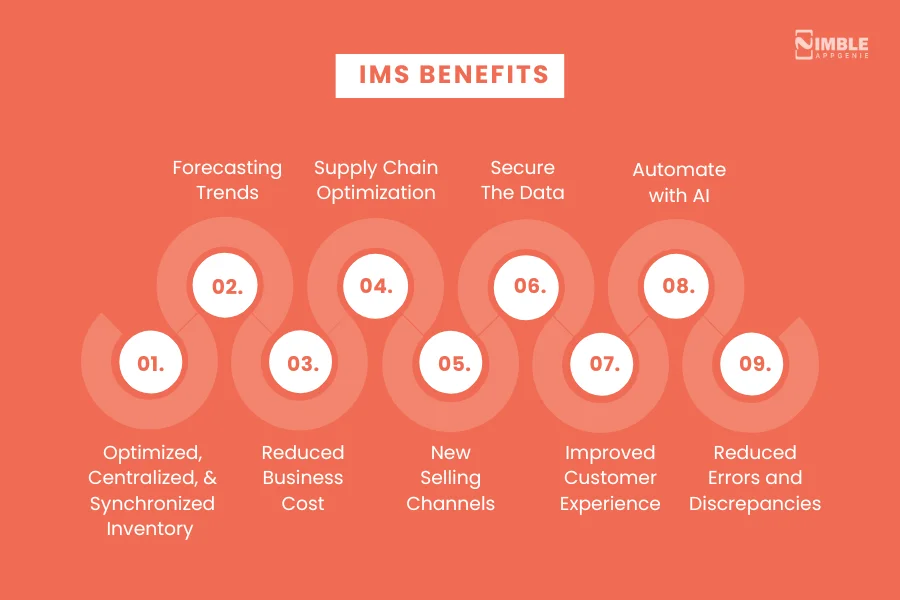

Benefits of Inventory Management Software Development

Is inventory management software development worth it? Should you hire dedicated developers and create inventory management software for your business? Can’t you do it without inventory systems?

These are just some of the questions people ask when considering this solution. And yes, you should have one. As for the reasons, we shall be discussing plenty of them.

Therefore, here are some reasons to hire dedicated developers today and build your own inventory management software.

♦ Optimized, Centralized, & Synchronized Inventory

You can be a one-location business or a multinational company, but you can’t underestimate the bliss that comes with organized inventory.

Let’s discuss the very first and biggest benefits of using inventory management software.

Companies often have issues with mismatched inventory at different locations, inaccurate results, and no record of lost or stolen items. All of these result in loss of business, not to mention the bad brand image and customer experience it sends.

But all of this can be solved with the help of inventory management systems.

Let us tell you how, you see, one of the core functionalities of inventory management software is to provide accurate data. Once you feed the data to the software, it will keep an accurate record with no chance of human error.

Moreover, enterprise-level inventory management solution also enables data-synchronization between different locations, streamlining the company’s inner working. And this gives us a whole lot of benefits that we shall be discussing in this section.

♦ Forecasting Trends

Let us tell you a business secret, if you want to be the next big thing or want to make your first billion dollars in profit, you have to make preemptive moves.

But how’s that possible? Not like you can look into the future, right? No, but what you can do is predict it.

Inventory management software will be processing and reading all of the data that you feed it. Meaning, it knows how much of what people are buying and when they buy it.

Based on this big data, inventory software generates a report with trends, forecasting capacities, and much more valuable information.

Recently, AI solutions have been integrated with inventory management software development to provide better and more accurate forecasting. And this has been working like a charm. The information you get from these reports can be used as a factor for important decision-making.

♦ Reduced Business Cost

Instead of asking “How much does an inventory management system cost?” you should be asking “How much does inventory management software system save?” Confused? Let us explain.

Inventory management system costs can reach hundreds of 1000s of dollars, which isn’t cheap. But this software is saving you more money than you realize.

If you look at statistics, you will realize businesses lose millions of dollars each year in lost items, misplaced inventory, loss of business due to unreliable tracking, and un-optimized processes. You can save all of this with modern and well-built inventory management software.

By fixing all the errors and saving time & effort via streamlined processes, this software is saving your business thousands or millions.

♦ Supply Chain Optimization

Supply chain is the thing that keeps the world running with a constant and steady supply of commercial and other goods.

What is a supply chain? As per Wikipedia, it refers to “it is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers”

The supply chain is built of many links including warehouses, logistics, manufacturing, factories, suppliers, retail stores, transportation, and so on.

Now, 80% of these links use (or can) inventory management systems in some way or another. This is why, if you improve inventory management, you improve the supply chain.

This is a pretty big thing considering, the supply chain loses companies billions of dollars due to inaccuracy, poor optimization, and fragmentation.

♦ New Selling Channels

Every business wants to grow, that’s the nature of the business world.

Now, coming to product-based companies, they have multiple channels to sell their goods. Presumably via their store to walk-in customers and online.

However, what if we told you that inventory management software allows you to do new selling channels without getting overwhelmed? Yes, that’s true.

One of the big reasons why businesses are limited to a few channels is difficulty to manage. For instance, they don’t know if they will have items in stock or how to manage an online order. This is something inventory systems will deal with.

With the help of a well-integrated inventory management software you can manage various selling channels at once.

And with this freed up capacity, businesses can focus on other areas. For instance, relevant to today’s market, one can develop a shopping app integrate it with the software and reach thousand more audience.

♦ Secure the Data

Item type, item number, procurement date, sale date, status, seller information, item location, cost of sale, cost of acquiring, and the data list goes on.

The amount of data generated by a company handling inventory is enormous. This leads to the issue of data loss, data security, and more. However, you can save all of that with your own inventory management system.

Being one of the leading benefits of inventory management software, it is a no-brainer to get this software, if your company is dealing with loads of data. This software will keep it organized, easily accessible, and synchronized across different locations.

This is quite a benefit of inventory management software in an age where privacy is super important.

♦ Improved Customer experience

Whether you deal with in B2B or your customers are end users, customer experience matters a lot. This is something all of us can agree upon.

Let’s first see, what the things that can spoil the customer experience are, and how inventory management software can help you improve it.

Problem: When you speak of retail businesses, one of the biggest issues that causes a bad user experience is a customer walking in, and a business not being able to provide them the item they want. This happens even when businesses show they have items in stock, this was for B2C. In the case of B2B, poor inventory management can lead to not meeting the deadline or failing to meet the order at all.

Solution: Inventory Management Software.

Here’s how, when you build inventory management software, you can add functionality of streamlined inventory, update on items out-of-stock, and reordering schedule. Moreover, you don’t have to manually check for information, which enables you to stay up-to-date at any given time.

This saves a lot of time, money, and most importantly, your brand reputation.

♦ Automate with AI

AI solution development is growing quite popular on its own and rightfully so. Artificial intelligence delivers what it promises.

There are a lot of manual processes in inventory management that give the team hell. But not anymore, AI can and will automate all the repetitive and boring tasks, saving a lot of time and also reducing the chances for error.

We are talking about:

- Demand Forecasting

- Reorder Point Calculation

- Stock Replenishment

- Inventory Tracking

- Inventory Valuation

- Supplier Performance Monitoring

- Stock Rotation

- Inventory Auditing

- Order Fulfillment

- Shelf Restocking

- Returns Management

- Expiry Date Management

- Price Adjustments

- Data Entry and Documentation

- Customer Demand Analytics

- Compliance and Regulatory Reporting

And much more.

Sounds amazing, right? This is your reason for make inventory management software. Speaking of reducing human error, this brings us to our next point.

♦ Reduced Errors and Discrepancies

Humans aren’t robots – now that’s a good thing and a bad thing. Good things, we are creative, we give rise to new ideas, make the world a better place, and so on.

Bad thing as in, we aren’t made to manage inventory via pen and paper, writing down hundreds of numbers. But if we are to do that, it will lead to a lot of errors and discrepancies, giving us what’s called human error.

So, what’s the best way to avoid human error? The answer is simple: leave this boring to machines and focus on creative things. In layman’s terms, leave it to inventory management software.

As simple as that.

So, these are the top benefits of inventory management software. Also the reason to invest in inventory management software development. With this out of the way, we shall be discussing the best inventory management software to get inspired in the section below.

Top Inventory Management Software To Learn From

If you want to create inventory management software, you need inspiration. And who better to learn from than the best inventory management software in the market?

That’s why, in this section of the blog, we shall be going through 5 top inventory management software. Let’s get started with the biggest one, which is:

► Oracle Supply Chain Inventory Management

The first one on our list is Oracle Supply Chain Management (SCM)

SCM is a market-leading software from a well-known organization and it lives up to its reputation. Being a top inventory management software, Oracle SCM helps businesses adapt to ever-changing demand, supply, and market conditions.

To provide better optimization, this inventory software integrates well with the supply chain and creates a resilient network.

All in all, the platform helps unify different systems like yard management systems, HRMS, CRMs, and so on.

Features:

- Supply Chain Planning

- Inventory Management

- Manufacturing

- Maintenance

- Order Management

- Logistics

- Product Lifecycle Management

- Procurement

- Blockchain and IoT

- SCM Analytics

Pricing: Custom pricing is based on the availed solution and capacity.

► Unicommerce Inventory Management

Do you want to unify your commerce channels and improve the business? Well, this is the one for you.

The platform serves more than 15,000 Sellers, Retailers, and Brands. Unicommerce offers unmatched superior inventory management solutions with which businesses can achieve higher sales, lower operating costs, lower manpower costs, and better data visibility.

This is a really big name in the inventory management software industry. After all, it is the system used by top brands like Hamilton Housewares, Enamor, Jack &Jones, Chumbak, Liberty Shoes, W, House of Anita Dongre, MCaffeine, Sugar Cosmetics, etc

Features:

- 3PL Management

- Alerts/Notifications

- Backorder Management

- Barcode/Ticket Scanning

- Barcoding/RFID

- Cataloging/Categorization

- Channel Management

- Cost Tracking

Pricing: Price starts from $100 Per month.

► NetSuite Inventory Management

In this inventory management system guide, we have mentioned talked about AI-powered inventory management software a lot.

It’s time to look at one. NetSuite Inventory Management

NetSuite is known for its automation prowess. The software helps you automate manual and repetitive tasks making the following a lot easier: traceability, replenishment, cycle counting, and managing inventory across multiple locations

Moreover, the platform is super simple to use with a single view for all the important information. As one of the best inventory management systems in the market, it helps businesses carry less inventory on hand and free up funds.

Features:

- Replenishment

- Cycle count

- Traceability

- Warehousing

- Inventory management

- Order fulfillment

- Availability

- Bin Management

- Inventory alerts

- Work Order Management

Pricing: NetSuite implementation can range between $10,000 and $100,000.

► Zoho Inventory Management

Zoho Inventory is a popular inventory management software.

Coming from a trusted brand, this online application helps businesses manage their order and optimize inventory is an online application that enables you to manage orders and inventory. With multi-channel selling, shipping integrations, and powerful inventory control, you can now optimize your inventory and order management, right from purchase to packing, to payments

Features:

- Multi-Warehouse Management

- Item Grouping and Bundling

- Serial and Batch Tracking

- Sales Order Management

- Invoicing

- Zoho Analytics

- Advanced Multi-Currency Handling

- UoM Conversion

- Purchase Order and Billing Solution

- Back Orders and Drop Shipments

Pricing (cost per month, billed per annum):

- Standard Plan (Per Organization)- $ 29

- Professional Plan (Per Organization)- $ 79

- Premium Plan (Per Organization)- $ 129

- Enterprise Plan (Per Organization)- $ 249

► Cin7 Inventory Management

Lastly, we have Cin7.

This is an inventory management solution specifically designed for manufacturers and product sellers. Cin7 is a great option for all types of small businesses. This covers retailers, wholesalers, and online sellers.

Coming to its function, it is a great platform as it helps manage inventory easily, get deep insight into sales on the go, and track stock movement in a super detailed view.

Features:

- Monitor 3PL providers.

- Real-time stock visibility.

- Advanced Manufacturing

- Automation

- B2B Payments

- Sales

- Warehouse Management

- Reporting and Forecasting

Pricing (cost per month):

- Standard Plan – $ 349

- Pro Plan – $ 599

- Advanced Plan- $ 999

- Omni Plan – Custom Pricing

Custom Inventory Management Software Development vs Ready-Made Inventory Management System

Going through the top inventory management software, a thought often appears in mind “Why should I build custom inventory management software, isn’t using a ready-made solution just better?”

You aren’t half wrong. For some businesses, ready-made inventory management software might just do it. On the other hand, no amount of customization to the ready-made solution will make it fit for the business.

So, the trick here is to identify which is the right choice for you. To help you with that, here’s a table:

| Aspect | Custom Inventory Management Software | Ready-Made Inventory Management System |

| Development Time | Since it is developed on specific requirements, it takes longer to design, develop, test, and deploy the software. | Since it’s ready made, implementation is super quick and you don’t have to deal with development time. |

| Customization | The name says it all: custom inventory management software gives you total control over customization, fulfilling your unique business needs. | Here, there is a strict limit to customization. Although it does allow for some custom functionality, that adds to the time. |

| Cost | The cost to create inventory management software highly depends on project specifications. | Here, the cost of an inventory management system is lower upfront, but involves ongoing subscription or licensing fees. |

| Scalability | Custom inventory system development delivers ultimate scalability. | Scalability highly depends on the software provider and plan. |

| Integration | Custom inventory management software systems can be integrated seamlessly. | There’s limited integration capacity in ready-made inventory systems. |

| Maintenance & Support | It requires ongoing maintenance and support. This can be more resource-intensive but offers full control over updates. | This solution comes with vendor-provided maintenance and support. This reduces the burden on business. |

| Training & Onboarding | Being a custom solution, to use it staff need comprehensive training. | Ready-made systems often come with training resources and might be easier to onboard staff. |

| Security | The business has full control over security measures. This also means business is responsible for security testing & related ops. | Security is usually managed by the vendor, but you have less control over it. |

This is a full-on comparison of custom inventory management software vs ready-made inventory management software. And with this out of the way, there are two ways you can go: either go with a ready-made one or build your own inventory management software.

If you are going for the latter one, let’s discuss the tech stack required to build such a solution.

Tech Stack for Inventory Management Software Development

Choose to make inventory management software? Well, if you are going to do that, you must understand the concept of “tech stack”

Inventory Management Systems Stacks refers to the set of technologies used to build inventory management software. This includes the back end, front-end, database, and everything else related to the development.

No, it’s super important to choose right tech stack for inventory management software that fits well. Why? Because it can affect inventory management software development time, cost of inventory management software, and other things.

Speaking of which, let’s look at the tech stack options we have here:

| Components | Technology Options |

| Database Management System (DBMS) | MySQL, PostgreSQL, Oracle, Microsoft SQL Server, MongoDB |

| Backend Development | Node.js with Express.js, Ruby on Rails, Django (Python), ASP.NET (C#), Java with Spring Framework |

| Frontend Development | HTML, CSS, JavaScript, React, Angular, Vue.js |

| APIs | Custom APIs for communication between frontend and backend; potential integration with other systems |

| Mobile Application (Optional) | React Native, Flutter |

| Cloud Services (Optional) | AWS, Azure, Google Cloud |

| Inventory Scanning and Tracking | Barcode scanners, RFID readers with Bluetooth and USB connectivity |

| Data Warehousing (Optional) | Amazon Redshift, Google BigQuery |

| Security Tools and Practices | Encryption, authentication, authorization, intrusion detection, firewalls |

| Version Control and Collaboration Tools | Git for Version Control, Slack, Microsoft Teams |

| Reporting and Analytics Tools | Tableau, Power BI, custom reporting features |

| Monitoring and Error Tracking | Prometheus, Grafana for monitoring, Sentry, Rollbar |

| Containerization and Orchestration (Optional) | Docker containers, Kubernetes |

| Caching | Redis, Memcached |

| ERP Integration (Optional) | SAP, Oracle E-Business Suite |

Done with the Inventory Management Systems Tech Stacks, we are one step closer to learning how to create inventory management software. Next up, we have a feature for inventory management software. So, let’s dive into it.

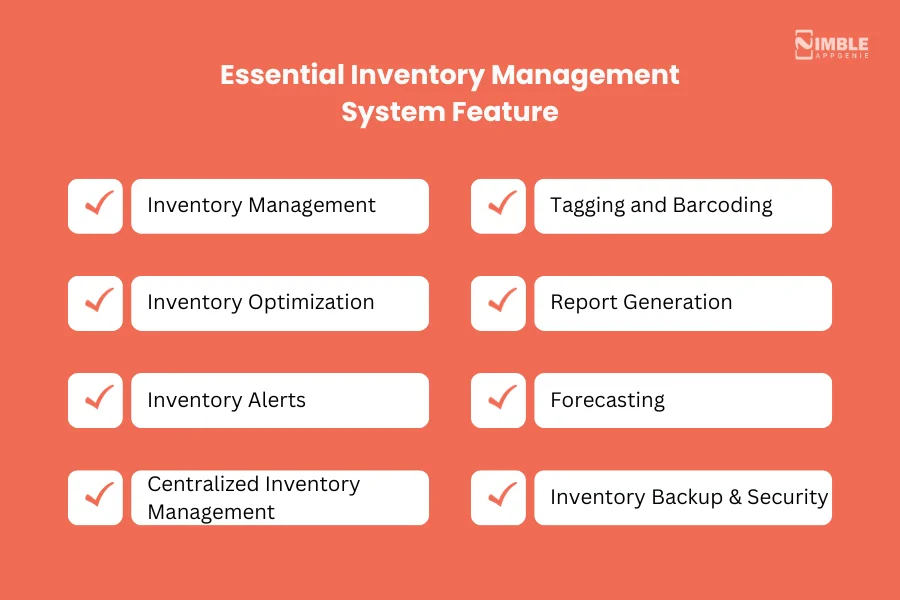

Essential Inventory Management System Features

We can’t stress things enough “FEATURE ARE IMPORTANT” more so than ever when you are building an inventory management system for your business.

Reason being, they provide you:

- Competitive advantage

- Enable scalability

- Improve productivity

- Make compliance easier

- Fulfill your business’ specific needs

- Allows smooth integration with other tools your business is using

- Making it easier for the team to use inventory management software

And much more.

Now that we have set the tone for the importance of inventory management system features, it’s time to discuss which features to choose.

Here’s what we are going to do, first, let’s discuss essential features. After this, we will dive into creating custom features as per business needs.

Therefore, let’s get right into it:

1. Inventory Management

The very first and core inventory management system feature is inventory management. How does this work? The software runs on data fed to it by the team which includes the number of articles, their type, quantity, seller information, reorder point, and so on.

Based on this, businesses always get in-depth insight on the inventory at any time, making management that much easier. The platform with AI integration also automates a lot of different processes.

2. Inventory Optimization

As we discussed in the previous feature, the software has all the data related to inventory, and using this, the software helps businesses reduce error, reduce inventory at hand, improve effectiveness, improve productivity, and reduce running costs.

All of this leads to a far more optimized inventory. Speaking of which, this is yet another core functionality of inventory management software.

3. Inventory Alerts

Inventory is exhaustible, however, it is important to keep a record of it and send the purchase order in time to keep everything sailing smoothly.

This is exactly what we do with the inventory management system. Here, you can set “reorder points” and set alerts. Whenever an item reaches this point the system will send an alert.

4. Centralized Inventory Management

There are many businesses across the world that are spread over different locations, cities, or even countries. And their supply chain can be traced back to a few factories or warehouses.

Now, with the help of inventory management software, the company can get a synchronized database across all the different locations. Thus, giving centralized inventory management functionality.

5. Tagging and Barcoding

Now, this one is not applicable to every business that uses inventory management, but hear us out: If a business uses a tagging and barcoding system to keep a record of its inventory or plans to introduce the same, there’s a feature that can save a lot of time.

You see, the solution directly connects with the tagging and barcoding machines thus, feeding data directly to the database. This happens in real-time on the company’s network.

6. Report Generation

Reports are the eyes of business, especially in larger businesses and enterprises. That’s why the report generation inventory management system feature is a must.

Using all the information from the database and one that is processed through the software, inventory management software will generate an in-depth report. This is a functionality that can be taken a step further with the help of AI integration.

7. Forecasting

If reporting is in the right eye then forecasting is the left one. And it’s pretty cool too.

For decades, businesses have relied on analysts to process the data manually and deliver market forecasting. In fact, there are entire companies based on this single activity some of which we discussed in the statistics section.

However, in Industry 4.0, the software is capable of delivering in-depth forecasts based on the data they are fed. And trust us on this one, these are pretty accurate.

8. Inventory Backup and Security

We have said this before and we will say this again: inventories create huge databases. And as unfortunate as it is, databases are vulnerable to corruption.

This is where inventory software’s backup and security features come in. First of all, the data on software is protected by several layers. And even if there is corruption to the database, backups of the same are always kept in a safe location.

So, these were some essential features. And with this out of the way, it’s time to create our own custom features.

How to Create Custom Features for Your Business Needs?

Every business is different and needs to ask for different inventory management system features & functionality.

But how do you know which custom features you need? Well, here’s how:

- Define Needs

- Ask Stakeholder & Workforce for their input

- Conceptualize the feature

- Set functional requirements

- Is it possible to develop it?

- Development

- Testing & User Feedback

- Optimization

- Implementation

Speaking of which, now that we are done with it’s time to get right into the inventory management system development process.

Inventory Management System Development Process & Implementation

It’s time to answer one of the most important questions “How to Create Inventory management software?”

We have come to the part of the inventory management software development guide, where we shall be discussing the detailed software development process for inventory management software.

Therefore, with this being said, let’s get right into it:

Step 1: Understand the Requirements

Every business is unique in the way that they have different niches, strategies, and consequently, requirements.

That’s why the first step is requirement analysis. And here’s how it’s done:

- Identify key stakeholders and departments

- Interview them for their requirements & opinions

- Divide requirements into different categories i.e. group them

- Functional requirements

- Operational requirements

- Technical requirements

- Transitional requirements

- Interpret requirements

- Verify and validate

- Review and approve

- Get Feedback

- Optimize the final draft

This is very, very important considering it will fuel the entire inventory management software development process. To take it a step further, you can use the required tools.

In any case, once we are done with the required audit, we move to the next process, where we will deal with planning for software development.

Step 2: Project Planning

Before we build inventory management software, we need to plan it and that’s what we shall be doing in the second step of the process.

We are already done with the required audit. Now, what we need to do is deal with the following:

- Deal with important documentation

- Define tech stack

- Choose software development methodology

- Plan out the feature list

- Set meeting interval

- Finalize delivery dates and deadlines

Sounds good enough? Well, project planning is quite an important aspect of the entire development thing considering it can affect the final product.

Therefore, it’s highly recommended that you take your time. But when you are done with this, we get to the heavy lifting.

Step 3: Inventory System Development

It’s time to build custom inventory management software.

This is the single most resourced and time-intensive step of the entire process. In fact, it is more like a process of its own than a step.

Therefore, in a bid to help you better understand the inventory management system development; let’s divide it into small, digestible steps.

Let’s start with the first one.

Designing

In this step, the designers of the team will create a UI/UX design. This deals with the front end i.e. the client side.

Despite being a software where only a limited number will be using it, creating a design that is easy to navigate and use is super essential.

Inventory Management System Development

Now that we are done with the design, we write code. This is also part of the development where inventory management software features are created and implemented.

Consequently, it is a very complicated part of development. For the same reason, it’s highly advised that you maintain good communication with software developers.

Now that we are done with this, we move to the next big step i.e. integration.

Step 4: Third-Party Integrations

Third-party integration refers to the process of adding third-party APIs and toolkits.

The goal of this step is to, use already existing solutions that excel at their individual task rather than developing them from zero.

Now, depending on specific business needs, tools and APIs used can differ widely. These can include report-generating software, forecasting systems, communication systems, and so on.

Step 5: Testing

When all the development is done, it’s time to test. There are various forms of testing, for instance, beta testing, automated testing, etc.

This is important to ensure the product doesn’t have any bugs of issues or errors left in the final product. Following the feedback from the QA team and the business, final adjustments are made.

Step 6: Inventory Management Software Implementation

With all that said and done, it’s time to deploy inventory management software.

The more suitable word for this process is “implementation” as the software isn’t posted on a marketplace place rather implemented in the company’s network and system.

Step 7: User Training

With the implementation done, there’s one final thing that remains and this is user training.

Since we are dealing with custom software here, there are a number of things that will be new to staff that will be using it. This is especially true for a business that is moving from manual processes to software.

Here, you get a good documentation guide for users, similar to what one CRM Development Company delivers when they create a custom solution.

Step 8: After Launch, Support and Maintenance

While the inventory management solution is deployed, the work for the developer isn’t over yet. Whether you do it in-house or outsource it, this process is a must.

You see, the software is stable but they ought to have some issues sooner or later. In addition to this, business requirements are constantly changing meaning a quick fix or little customization is needed from time to time.

This is what we deal with in support and maintenance services.

So, this is the entire inventory management solution development process. Now, in the next step of this guide, we shall be discussing “cost of inventory management software”

How Much Does It Cost to Develop Inventory Management Software?

Businesses love to ask questions like: How much does this cost? How much does it cost to build a custom CRM software? And in this case, how much does an inventory management system cost?

But this is a question that isn’t all that easy to answer.

On average cost to develop an inventory management system ranges from $15,000 to $150,000 depending on various factors. These include:

- Size of software

- Tech stack used in development

- Location of the development team

- Development duration

- Complexity of the solution

- Implementation and training process

And much more.

Amidst all of this, if you are looking for an accurate cost of inventory management software estimation, it is highly recommended that you consult an inventory management software development company

Based on your project specifications, they will be able to deliver an in-depth cost breakdown and development timeline.

Technology Trends in Inventory Management Software

With the recent growth inventory management market is to be valued at around USD 2998.55 Million by 2028, showing a CAGR of 11.9% from 2021 to 2028.

This shows some serious growth. This is driven by some market and technological trends. So before we conclude our inventory guide for inventory management software, let’s look at inventory management software trends.

These are, as mentioned below:

♦ Cloud-based solutions

This is a trend that has been around for a long time now.

As the name suggests and as we have already discussed in this blog earlier, Cloud inventory management software is only different in one way, they are stored and work in the cloud.

Thus, making them much more accessible on different devices while also enabling real-time data synchronization.

♦ Distributed Inventory Management

So, what is Distributing Inventory Management?

As the term suggests, it refers to an inventory that is located across multiple warehouses. Now, this can be used to our advantage by strategically placing inventory in specific locations based on their demand and need.

This can reduce transportation costs and speed up delivery times. Now, this is a functionality that has been integrated with several inventory management systems and you can also cover it in your.

♦ Predictive picking

Every business wants an improved order fulfillment process as it can highly improve productivity and optimize the supply chain.

Predictive pick-up functionality can be integrated into inventory management software development and can be used to direct businesses to start fulfillment processes even before the order has been placed.

As such, this trend branches off from the forecasting we discussed earlier.

♦ Automation

Well, well, this is a trend that everyone was expecting to see sooner or later. Well, we talked about leaving repetitive tasks to robots and that’s what automation is all about.

This is a trend that is already well set in the industry as larger companies like Amazon are already using warehouse robots and automated devices in their workplace. This highly promotes productivity and improves overall streamlining.

♦ Artificial Intelligence

Last but one of the biggest inventory management software trends is the use of AI.

Artificial intelligence is being used throughout industry 4.0 to improve outcome and create better results with less human effort.

Moreover, this also helps in prediction and forecasting, helping businesses prepare for an ever-changing market.

These are some top trends that you should include in inventory management software development. Speaking of development, if you want to create an inventory management software of your own, what you need the most is a development partner. This brings us to our next step….

Why Should You Choose Nimble AppGenie?

To create inventory management software that fulfills your business needs, you need an innovative and dedicated development partner. This is where Nimble AppGenie comes in.

With years of experience in custom software development for enterprises and companies across the world, we have the expertise required to develop tailored inventory management software for your business.

Our expertise as an inventory software management development company is recognized by top platforms like Clutch. co, GoodFirms, and many others. Furthermore, our inventory management system development services are unmatched in the market.

In addition to having an experienced team of professional developers, we are set apart from others by our dedication and the innovation we bring to the table. What starts with an idea, we give it a digital life and keep it relevant for you with our maintenance and support services.

If you want to create an inventory management system, we are here to help you. Give us a chance to bring your ideas to life. Dare be great, we’ll help the process.

Conclusion

The supply chain went through a huge transformation following the Covid pandemic. This forced industries across the world to adapt to better and more innovative mediums. Even without the recent change, inventory management stands out as a practice that can greatly help businesses optimize their way to higher revenue and reduce operating costs.

Comes in: inventory management software. This software is specifically designed to help your businesses manage the inventory at hand, purchase order placing, optimization, and the list goes on. The end result? An optimized inventory that runs on low operating costs while also giving real-time insight and forecasting.

This is why you must create inventory management software for your business. And in this blog, we discussed everything related to that.

FAQ

The term “inventory management software” refers to a system that helps in the management and automation of inventory. The capabilities of inventory management software include tracking inventory, procurement, updating accounting data, synchronization across different locations, and much more.

If you want to create an inventory management system, here’s the process you need to follow:

- Requirement audit

- Plan the development

- Software Design

- inventory management software development

- Third party integration

- Testing

- Deployment

- User training

- Maintenance and support

The programming languages used for inventory management software development depend on the scope of the project. However, some commonly used ones are Flutter, Xamarin, Bootstrap, etc.

The average cost to develop an inventory management system ranges from $15,000 to $150,000 depending on various factors. For a detailed cost estimate, we recommend that you consult an inventory management software development company.

Key features that every inventory management software includes are:

- Inventory backup and security

- Forecasting of the inventory

- Report Generation

- Tagging and Barcoding

- Centralized Inventory Management

- Inventory Alerts

- Inventory Optimization

- Inventory Management

There are a number of top inventory management software available in the market. Some of these are, as mentioned below:

- Zoho Inventory

- Cin7

- NetSuite Inventory Management

- Unicommerce

- Oracle SCM

Niketan Sharma is the CTO of Nimble AppGenie, a prominent website and mobile app development company in the USA that is delivering excellence with a commitment to boosting business growth & maximizing customer satisfaction. He is a highly motivated individual who helps SMEs and startups grow in this dynamic market with the latest technology and innovation.

Table of Contents

No Comments

Comments are closed.